A new type of wall production line with an annual output of 150 million yuan. The project produces products that utilize waste recycling. Building foundation soil, washed sand sludge, coal gangue, etc. are used as raw materials for sintered bricks. The raw materials are fed through a soil supply box and mixed proportionally through a conveyor belt before entering the crusher for fine crushing. There is some noise when the crusher processes the raw materials, so closed noise reduction treatment is considered; The crushed raw materials enter the rolling screen machine for particle screening, during which dust is generated. Therefore, the environmental design considers using one large dust collector for dust removal treatment to ensure that the dust concentration meets the national emission standards; After adding water to the first mixer for mixing, the raw materials contain 13% to 15% moisture, and there will be no production dust generated thereafter.

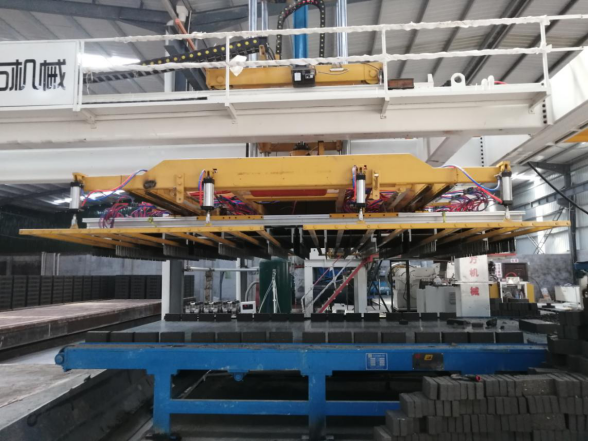

The processed raw materials are stacked in the aging warehouse to improve their plasticity. The aged raw materials are shoveled into the feeder by a shovel truck. In order to ensure the quality and output of the production products, Dongfang Machinery uses a hard plastic extrusion molding one-time firing process according to the actual situation. The main machine uses a JKY70-65 two-stage vacuum machine with high extrusion pressure and high vacuum degree of hard plastic extrusion molding, a servo billet cutting system for cutting strips and blocks, and a fully automatic billet coding system to code wet billets onto the kiln car. Using a kiln car as a carrier, the stacked bricks are transported to the drying kiln, and the waste heat from the roasting kiln is sent to the drying oven by a fan for drying. After drying, the bricks are transported by a shuttle car to the roasting oven for cultivation and sale.

The full process automation has high intensity, saves labor, reduces costs, and improves efficiency. Due to the use of the "full internal combustion" roasting process in this project, thermal energy is brought in from coal slag. The main substances in the smoke generated during the production process of tunnel kiln roasting of bricks are SO2 and smoke. Therefore, a set of 95% desulfurization tower device is selected to desulfurization and dust removal this part of the flue gas, so that the emission concentration of smoke and SO2 is lower than the industry standard of the national "Emission Standard for Air Pollutants in Brick and Tile Industry". The main types of production wastewater include: cooling water for fans and water for vacuum pumps, which do not contain toxic or harmful substances. After oil separation and decontamination treatment, they are directly discharged through drainage ditches. After taking the above measures, the noise, exhaust gas, and wastewater of the production line can all meet the national environmental protection requirements. Not only will it not cause damage to the natural environment, but waste recycling is more energy-efficient and environmentally friendly.